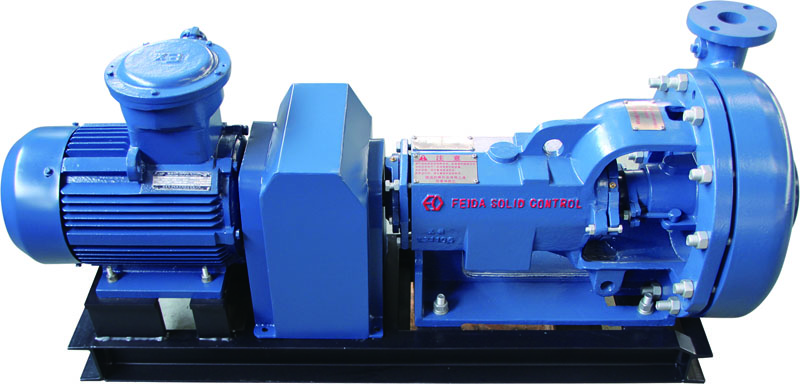

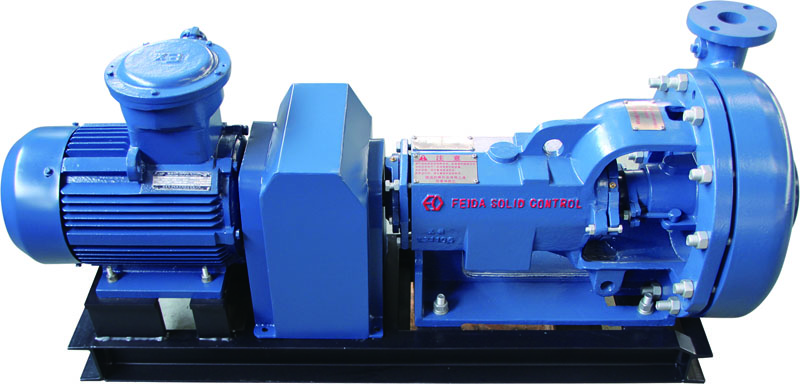

砂泵系石油钻井泥浆循环系统的重要组成部件,它采用轴向吸入结构,叶轮为耐磨耐腐蚀材质加工制作,适用于输送带有悬浮颗粒的钻井液或其他类似工况的液体介质。

SB系列砂泵在设计上主要有以下几个特点:

a.复合式机械密封:采用机械密封,同时外侧辅以盘根密封,比传统采用纯盘根密封更为可靠。

b.开放式叶轮结构:设备叶轮采用了开放式的结构设计,使轴的载荷减小到最低,运行更平稳。

c.流量和效率更高:叶片曲线更符合流体力学要求,提高了设备的流量和效率。

d.使用寿命更长:关键部位采用了耐磨抗腐蚀材料,抗磨损抗腐蚀,延长设备的使用寿命。

e.轴向调节结构:采用轴向调节结构,方便调整叶轮的前后间隙,提高运行效率。

f.精准的加工手段:零部件完全采用数控机床加工,相同零件可以完全无差别互换。

g.选用范围更广:多种型号的泵壳和叶轮,满足客户的多种需求。

砂泵工作原理:

液体通过泵壳进口连接管到达叶轮吸入口,通过高速旋转的叶轮,在惯性离心力的作用下自叶轮中心被甩向周边并获得能量,使流向叶轮周边的钻井液静压强提高,流速增大。液体离开叶轮进入泵壳后,在惯性力作用下随泵壳流道运动,具有较高压能的液体在泵壳内腔切线出口进入排出管道,被输送到指定的管路系统中。

砂泵常见故障及排除方法:

序号

No. | 故障现象

Failure | 产生原因

Cause | 排除方法

Troubleshooting |

1 | 流量不足

Insufficient flow | 吸入闸门未全开

Inhale gate not opened.

泥浆罐液面过低

Liquid level for mud tank is far too low.

沉砂堵塞滤网

Settled sand clogging filter screen.

吸入管漏气

Inlet duct found with leakage.

电机反转

Motor reversal. | 打开闸门

Open the gate.

提高泥浆罐液面

Raise the liquid level for mud tank.

启动搅拌器

Start up the agitator.

修复吸入管路

Repair the inlet duct.

电工调整相线

Phase wire to be adjusted by electrician. |

2 | 振动明显

Apparent vibration | 吸入闸门未全开

Inhale gate not opened.

泥浆气浸严重

Severe gas influx to mud.

泵与电机不对中

Pump not matched to power generator.

轴承损坏

Damaged bearing.

地脚螺栓松动

Loosened anchor bolts.

基础不牢

Foundation not firm.

固定松动

Loosened fastening. | 打开闸门

Open the gate.

将泥浆除气

Exhaust gas from mud.

重新找正并紧固

Have it readjusted and fasten firm.

更换轴承

Replace the bearing.

拧紧地脚螺栓

Fasten anchor bolts firm.

加固基础

Consolidate the foundation.

加强固定

Secure the fastening. |

3 | 异常响声

Abnormal sound | 压盖与轴套磨擦

Pressure cover in friction with axle sleeve.

叶轮松动

Loosened impeller.

轴承润滑不足

Insufficient lubrication grease for bearing.

气蚀

Gas etching. | 重新调整压盖螺栓

Readjust the bolts for pressure cover.

上紧转子螺母

Fasten rotor nut firm.

添加润滑油

Add more lubrication grease.

降低排量

Lower down discharge. |

4 | 轴封泄漏

Spindle seal leakage | 轴套严重磨损

Axle sleeve seriously worn out.

盘根失效

Disabled packing. 轴承损坏

Damaged bearing. | 更换轴套

Replace the axle sleeve.

更换盘根

Replace packing. 更换轴承

Replace bearing. |

5 | 轴承发热

Over-heated

Bearing. | 盘根压得过紧

Packing being pressed too tight.

润滑油不足或过多

Insufficient or excessive lubrication grease.

润滑脂不干净

Lubricants no clean.

泵与电机不对中

Pump not matched to power generator.

轴承中有泥浆

Mud found in bearing. | 调松盘根压盖

Adjust packing pressure cover loose.

添加或放出润滑油

Add more or release lubrication grease.

更换润滑脂

Change lubricants.

重新找正并紧固

Have it readjusted and fasten firm.

清洗轴承,更换润滑油

Cleanse bearing and renew lubrication grease. | |

6 | 泄漏严重

Severe leakage | 油封磨损过大

Oil seal seriously worn out.

耐磨套磨损严重

Wear sleeve seriously worn out.

密封填料磨损过大

Seal filler severely worn out.

机械密封失效

Disabled mechanical seal. | 更换油封

Change oil seal.

更换轴套

Replace axle sleeve.

更换密封填料

Replace seal filler.

更换机械密封

Replace mechanical seal. | |

点击询价

电话:400-001-8976

电话:400-001-8976 邮箱:pengwl@fdpetrol.com

邮箱:pengwl@fdpetrol.com 地址:沧州经济开发区新华园区

地址:沧州经济开发区新华园区